Where Does My Drinking Water Come From? How LCA Collects, Treats and Transports Your H2O

July 14, 2020

Water, Water, Everywhere

Clean water is one of those things you take for granted: When you walk into the kitchen and turn on the tap, it just flows out. But did you ever stop to wonder, “How did my water get here? Where does drinking water come from?”

Over the next few blog posts, we’ll show you how water gets from source to tap, how it’s treated, how water quality is tested, and the steps we’re taking to replace and repair our water infrastructure.

The Lehigh Valley is a thirsty region. On average, the demand for water supplied by LCA to all of our customers — Allentown and our Suburban side combined — is about 24.5 million gallons per day.

We serve 20 municipalities via 14 systems that carry drinking water through 662 miles of pipes to 55,000 properties. In Allentown alone, there are 330 miles of water mains!

Drinking Water Sources

LCA draws water from 25 different sources. In Allentown, the Schantz Spring and Crystal Spring are groundwater sources that satisfy about half of our drinking water demand. The other half comes from surface water — with the majority of that coming from the Little Lehigh Creek. The Lehigh River acts as a secondary water source. Our Suburban customers get most of their water from Allentown’s sources, with some additional drinking water supplied from 21 wells scattered throughout our service area.

Our groundwater sources are exceptionally clean, so they need little treatment. After that water is collected, some chlorine is added to eliminate any possible pathogens — things like bacteria or viruses that could make you sick. Then fluoride is added, and it’s on its way through our series of pumps, tanks, and mains to your home.

Even though our surface water sources are generally clean, they’re not as pristine as groundwater, and so require a different treatment process (which changes with the weather).

Screen Time

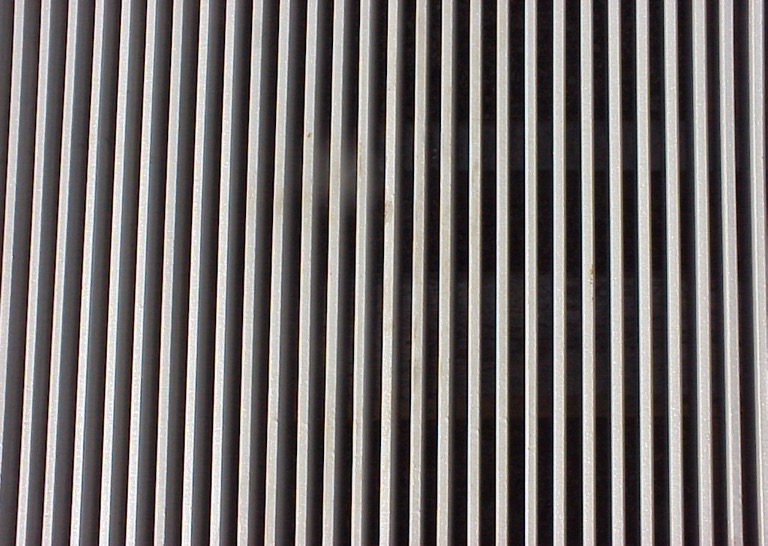

Treatment actually starts at the collection point, where containment booms block any oils from entering the water inlet. Then a coarse, wide screen made up of bars spaced 2.5” apart — like the one in the image to the left — captures big items such as leaves, sticks, and trash (including lots of plastic bags and bottles). Our workers must keep this screen clean by manually removing all the debris — no easy task, especially during the fall months when the leaves are dropping!

Next in line is a finer screen, which removes many of the smaller things that get past the coarse screen — things like bits of grass, more leaves, small sticks, and some algae. Still, some tiny debris gets through and can clog up water pumps and sample lines, so maintenance and attention to detail is always important.

One thing the finer screen doesn’t remove is the dirt particles suspended in the water — that’s what makes it look cloudy (the technical term is “turbid”). To remove these particles, we add a substance to the water called a “coagulant.”

In baking, a good example of a coagulant is an egg — it acts to bind together other ingredients. In the water, our coagulant causes the dirt particles to bind together so that we can remove them in a process called “settling.” This begins the disinfection process. These particles form into a solid, which is collected in tanker trucks and disposed of. The higher the cloudiness, or turbidity, of the water, the more coagulant must be used (and the more solids are produced).

The Chlorine Connection

At this point, we also add chlorine (just like the type used in a pool) using the equipment in the image to the right. This eliminates bacteria and viruses. The more “dirt” that is present in the water, the more chlorine is needed for proper disinfection. Then the water goes through a final filtration step to capture any microscopic particles that weren’t removed in the settling process.

Analyzers continuously monitor the water before, during and even after the treatment processes for things such as cloudiness (turbidity), pH, and levels of chlorine, fluoride and aluminum.

Our state-certified lab does much of the testing in-house, though some samples are also sent out for testing. The water samples are taken not just from our treatment facilities, but from sites throughout our service areas to ensure the quality is consistent. Testing consistently shows that our treatment process results in turbidity levels that are about ten times better than the EPA’s requirements!

Storage Solutions

Once the water is treated, it is then stored in what we call “finished water” reservoirs. Our Allentown division uses three: One holds 30 million gallons; the other two hold 10 million, for a total of 50 million gallons of water. Each feeds a different section of the city. On our Suburban side, we have four reservoirs that can store 10 million gallons of water.

In Allentown, we also have four high-level reservoirs (like the one at left) — the elevated tanks or water towers that you’re accustomed to seeing. These are located at higher parts of the distribution system, where the water pressure will be the lowest. These reservoirs aren’t just for day-to-day supply — they ensure we won’t run out of water in case of a fire or line break.

Typically, we fill those reservoirs over several days, and then reduce water production significantly to ensure that most of the water is used up before we add more. This keeps the water from becoming stale or losing the chlorine we’ve added (chlorine generally evaporates in about 24 hours). The water must always have a residual amount of chlorine to ensure no pathogens can develop within the reservoirs or distribution system. Although some people don’t like the taste of chlorine, this is very important to avoid sickness. (If you want to remove the taste of chlorine, allow a pitcher of water to sit overnight before drinking, or use a home filtration system. Read more about why we use chlorine and how to remove it here.)

Of course, all of the equipment we use — including the many miles of water mains — will eventually require maintenance or replacement. We’ll cover some of our upcoming infrastructure replacement projects in an upcoming post.

Questions or concerns about your drinking water? Check out our About Your Water page for information specific to your region, or contact our Customer Care Team.